Aesthetics

- Rich appearance options: Hot-pressed veneer offers a wide variety of colors, textures, and patterns, allowing it to mimic natural materials such as wood, leather, and carbon fiber. This versatility meets the demand for personalized and diversified automotive interior designs. For example, high-end car brands often use hot-pressed veneer with imitation wood grain to create a luxurious atmosphere or special textures to give a more modern, tech-savvy look.

- Good visual effect: Through precise hot-pressing, the veneer adheres tightly to interior parts, producing a flat, smooth surface with no defects such as blistering or wrinkles. This results in a high-quality visual effect that enhances the overall aesthetic of the vehicle interior.

Functionality

- Wear resistance and durability: Hot-pressed veneer is highly resistant to wear, making it ideal for automotive interiors, which experience frequent contact and friction. This durability ensures that parts like seats, armrests, and center consoles retain their appearance and performance over time.

- Anti-aging performance: Car interiors are exposed to sunlight, temperature changes, and humidity, which can cause aging and fading. Hot-pressed veneer, after special treatment, offers excellent anti-aging properties, maintaining its color and stability for a longer period.

- Easy to clean and maintain: Unlike some natural materials, the smooth surface of hot-pressed veneer does not easily attract dust and dirt, making it easier to clean. A simple wipe with a damp cloth and detergent is enough to keep the interior clean, reducing maintenance time and cost for vehicle owners.

Safety

- Good flame retardancy: Hot-pressed veneer can be treated with flame retardants to meet the safety standards of the automotive industry. This ensures that in case of emergencies, like fires, the spread of flames is minimized, providing passengers with more time to escape.

- Environmental protection: High-quality hot-pressed veneer materials often use eco-friendly adhesives and raw materials that are free from harmful substances like formaldehyde and benzene. This makes hot-pressed veneer a healthier choice for passengers and more environmentally friendly, which is increasingly important to consumers.

Economical aspect

- Low cost: Compared to natural leather or solid wood, hot-pressed veneer is a more cost-effective option. It allows automakers to improve interior quality while keeping costs manageable, meeting the needs of a wide range of consumers.

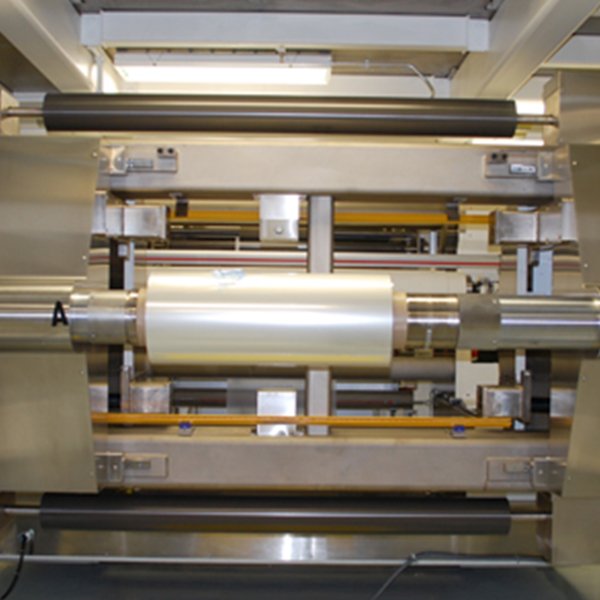

- High production efficiency: The hot-pressing process is highly automated, significantly improving production efficiency and shortening production cycles. This simple process also reduces labor costs and minimizes errors in production.