At Shenzhen JINQ Technology Co., Ltd., the oil edging process in coating technology involves several precise steps to ensure high-quality results:

1. Preparation

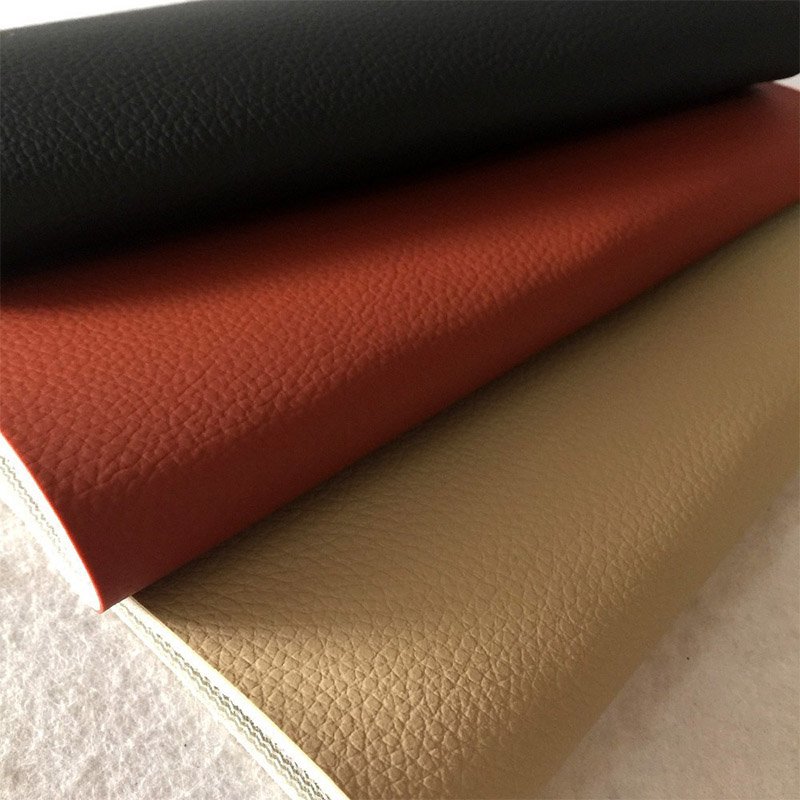

Material Preparation:

- Select the appropriate edge oil that matches the leather color.

- Prepare necessary tools such as oil edging pens, sandpaper, and cotton cloths.

Leather Edge Preparation:

- Use sandpaper to gently smooth the leather edges, removing any burrs and uneven areas. This ensures a smooth surface. Be careful to avoid over-sanding, which could damage the leather.

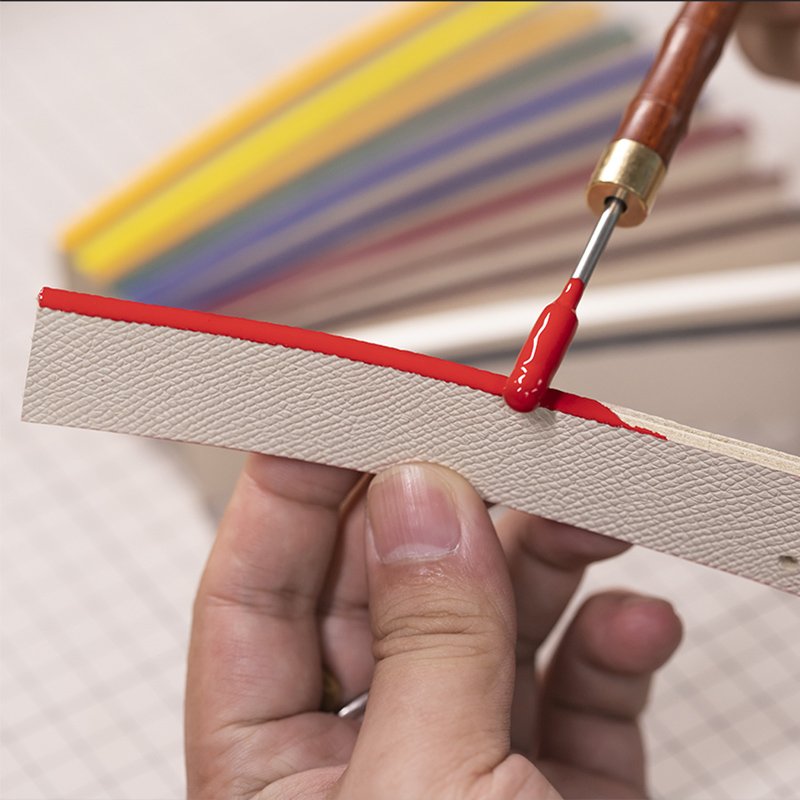

2. Applying the Oil Edging

First Coat of Oil:

Do you want to

CUSTOM YOUR PREMIER GOODS

JINQ provides expert leather wrapping services, including hot pressing, sewing, edge painting, and custom leather solutions for electronics, packaging, gifts, stationery, and automotive interiors.

- Using an oil edging pen, apply a suitable amount of edge oil evenly on the leather edges. Ensure the application is neither too thick nor too thin. Allow the leather to dry in a well-ventilated area.

Sanding:

- Once the first coat is dry, lightly sand the edges to remove any particles and smooth out any irregularities. Again, be cautious not to over-sand, which might expose the leather beneath.

Second Coat of Oil:

- Apply a second coat of edge oil with the oil edging pen. This coat can be slightly thicker to ensure a smooth and full edge. Allow it to dry completely.

Repeating Sanding and Oil Application:

- Depending on the desired finish, repeat the sanding and oil application process up to three to four times. This ensures that the edge oil is firmly applied and the edges are smooth and durable.

3. Finalizing the Process

Cleaning:

Do you want to

CUSTOM YOUR PREMIER GOODS

JINQ provides expert leather wrapping services, including hot pressing, sewing, edge painting, and custom leather solutions for electronics, packaging, gifts, stationery, and automotive interiors.

- Use a cotton cloth with a small amount of cleaner to gently wipe the leather edges, removing dust and any residue. Avoid excessive pressure to prevent damaging the oil edging.

Polishing:

- Polish the leather edges with a clean cotton or polishing cloth to enhance the smoothness and shine of the oil edging. Apply moderate pressure but avoid over-polishing, which could damage the surface.

Inspection:

- Conduct a thorough inspection of the finished leather edges to ensure they are smooth, free from cracks, and bubbles. Address any issues promptly to maintain quality standards.

The oil edging process at Shenzhen JINQ Technology Co., Ltd. is meticulously designed to deliver aesthetically pleasing, durable, and high-quality results. Different manufacturers may have variations in their processes, but the principles of multiple oil applications, sanding, and polishing remain consistent for achieving optimal leather edge finishing.