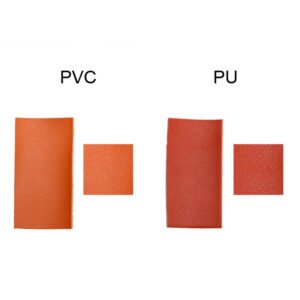

PU (Polyurethane) leather and PVC (Polyvinyl Chloride) leather are two widely used synthetic leather materials. Both have unique qualities and advantages, and while they share some similarities, there are distinct differences between the two. Here’s a breakdown of their pros, cons, and common features.

Advantages of PU Leather:

- Good Physical Properties: PU leather is flexible, durable, and has excellent resistance to bending and stretching. It also offers some breathability, making it more comfortable for prolonged use compared to PVC.

- Natural Feel: PU leather has a texture that closely resembles natural leather, offering a soft and smooth surface that enhances its appeal.

- Easy to Clean: PU leather is resistant to stains and easy to clean, making it suitable for a variety of applications.

- Variety of Treatments: The material can undergo various surface treatments and dyes, resulting in diverse textures and colors.

- Eco-Friendly: PU leather is more environmentally friendly than genuine leather since it doesn’t involve animal products. It’s also less toxic than PVC during production.

- Cost-Effective: While maintaining quality, PU leather is generally more affordable than natural leather, making it accessible for manufacturers and consumers alike.

Advantages of PVC Leather:

- Durability: PVC leather is known for its exceptional resistance to wear and tear, maintaining its appearance for long periods.

- Water Resistance: It is highly water-resistant, making it ideal for items exposed to moisture, such as upholstery and car interiors.

- Low Maintenance: PVC leather is easy to clean and doesn’t absorb dust or stains easily. A quick wipe with a wet cloth is usually enough to keep it looking good.

- Cost-Effective: PVC leather is one of the cheapest synthetic leathers available, offering a wide range of colors, including transparent and candy-like hues.

- Chemical Resistance: It’s resistant to acids, alkalis, and temperature variations (up to 65°C), making it a good choice for industrial use.

Disadvantages of PU Leather:

- Limited Durability: PU leather isn’t as durable as PVC and is more prone to wear and tear, such as scratches and peeling over time.

- Sun Sensitivity: Prolonged exposure to sunlight can cause the material to crack or wrinkle.

- Cleaning Limitations: PU leather can only be cleaned with water below 40°C and is sensitive to dry cleaning.

- Higher Cost for Specialty PU: Certain types of PU leather with advanced features, such as high breathability or a superior texture, can be more expensive.

Disadvantages of PVC Leather:

- Poor Breathability: PVC lacks the breathability of PU, which can make it uncomfortable during long periods of use, particularly in hot environments.

- Environmental Impact: The production of PVC can release harmful chemicals into the environment, and improper disposal of PVC products may contribute to pollution.

- Less Natural Feel: PVC leather tends to feel less like natural leather compared to PU, and it lacks the warmth and softness associated with genuine leather.

- Temperature Sensitivity: PVC is more prone to cracking, hardening, or degrading at higher temperatures or with extended exposure to sunlight.

Similarities Between PU and PVC Leather:

- Synthetic Alternatives to Leather: Both PU and PVC are commonly used as substitutes for natural leather in industries such as fashion, automotive, furniture, and accessories.

- Cost-Effective: They are more affordable compared to genuine leather, offering manufacturers and consumers budget-friendly options.

- Water Resistance: Both materials provide a level of water resistance, making them suitable for products exposed to moisture.

- Customizable: PU and PVC leather can be modified with additives and pigments to achieve different colors, textures, and finishes, allowing for creative flexibility in design.

Conclusion

Both PU and PVC leather are valuable materials that cater to different needs. PU leather is preferred for its softness, eco-friendliness, and closer resemblance to natural leather, while PVC leather is favored for its durability, water resistance, and lower cost. Understanding their advantages, disadvantages, and similarities can help consumers and manufacturers make informed decisions based on the application, budget, and desired aesthetics.