The leather wrapping process involves covering an object’s surface with a layer of leather material. Its main purpose is to decorate, protect, or improve the performance of the object. Below are some common leather wrapping processes and their areas of application:

1. Automotive Interior Sector:

- Negative Mold In-Mold Textured Leather Wrapping Process: First, a negative mold with a textured leather pattern is used. A smooth film is molded inside the mold to form a textured surface with the shape of the interior part. This textured surface is then vacuum-adhered to the substrate at the same station. Compared to traditional leather wrapping, this process offers greater design flexibility, allowing patterns to remain on the edges, and different textures can be formed in one stage.

- Traditional Leather Wrapping Process: Pre-textured materials are heated and vacuum-formed over the substrate using a convex mold, or slush molding is employed, where powdered materials are used to mold the textured leather surface of the interior part. Polyurethane (PU) is then poured between the surface and the substrate to bond them together.

2. Furniture Manufacturing Sector:

- Adhesive Bonding Leather Wrapping: Leather is glued onto the frame or panel surface of furniture. This method is relatively simple but may face issues like aging of the adhesive over time, leading to separation between the leather and the frame, resulting in bubbling, delamination, or curling edges.

- Hot Melt Leather Wrapping: A hot melt structure is set on the furniture frame, and corresponding installation holes are made in the leather. After passing the hot melt structure through the installation holes, it is heated and melted to secure the leather onto the frame. This process is convenient and firm, without the need for additional fasteners or adhesives.

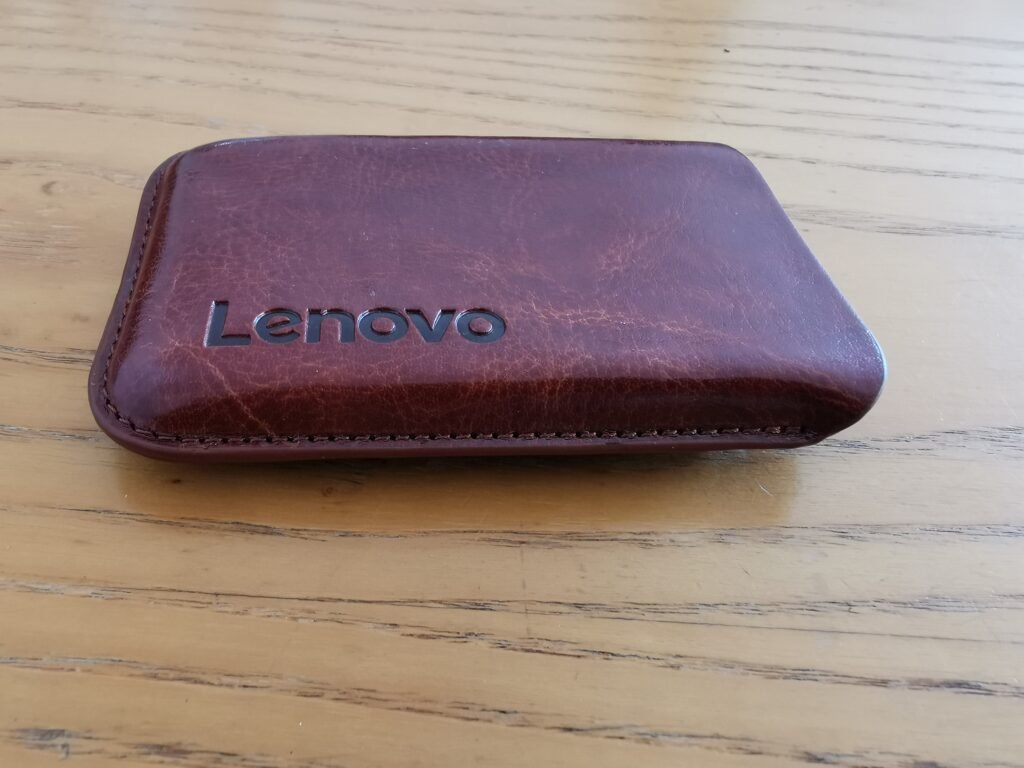

3. Electronics Sector:

Some electronic products, such as outer cases or handles, may use leather wrapping processes to increase grip comfort and aesthetics. For example, some high-end headphones have leather ear cushions, and the grips of gaming controllers may use leather or synthetic leather for wrapping.

Do you want to

CUSTOM YOUR PREMIER GOODS

JINQ provides expert leather wrapping services, including hot pressing, sewing, edge painting, and custom leather solutions for electronics, packaging, gifts, stationery, and automotive interiors.

4. Crafts and Luxury Goods Sector:

For some high-end crafts, musical instruments, cameras, and other items, the leather wrapping process can enhance their artistic value and sense of quality. For example, Leica once released a limited-edition camera with intricate Japanese-style leather wrapping, showcasing exquisite craftsmanship.