I. Overview of Uneven Hot Stamping Veneer Phenomenon

In export products, the issue of uneven hot stamping veneer frequently occurs, posing significant challenges to product quality and seriously affecting their competitiveness in the market. Hot stamping veneer is widely used in various export products such as furniture, decorative materials, and more. However, due to various reasons, uneven veneer often troubles manufacturers and exporters.

When the veneer is uneven, the appearance quality of the product suffers greatly. Uneven surfaces not only affect the visual effect but may also leave a poor quality impression on consumers. In the fiercely competitive export market, product appearance quality is often a key factor in attracting customers. If the veneer is uneven, customers may choose other products with better appearance, leading to a loss of market share for manufacturers.

Furthermore, uneven veneer may also affect the product’s performance. For example, in furniture, an uneven veneer can reduce comfort and durability, while in decorative materials, it may hinder the decorative effect and even cause installation difficulties.

According to statistics, quality issues caused by uneven hot stamping veneer account for a significant proportion of problems in export products. This not only brings economic losses to manufacturers but also affects the reputation of the entire industry. Therefore, analyzing the causes of uneven hot stamping veneer and implementing effective solutions is crucial for improving product quality and competitiveness in export markets.

II. Investigation into the Causes of Uneven Hot Stamping Veneer

1. Humidity and Moisture Effects

During rainy seasons or in humid climates, the moisture content in the air is high. The materials used in hot stamping, such as heat transfer film, are easily affected by external humidity and can become damp. When the heat transfer film absorbs moisture, its internal structure changes, and the moisture may cause the material to expand or deform. During the stamping process, this deformation manifests as surface unevenness. According to Qingyi Heat Transfer Printing, using a water-based ink with no odor for the white base is particularly susceptible to moisture in such environments. To resolve this issue, it is recommended to dry the heat transfer film again and store it in a dry place to prevent uneven surfaces caused by moisture absorption during the stamping process.

2. Uneven Printing Plate Pressure

When installing the plate, if the surface is uneven, it can result in inconsistent pressure across different areas. Some areas may have too much pressure, while others have too little, leading to uneven force distribution on the design. When stamping foil, the surface may not be smooth, and the adhesion between different parts and the substrate will vary, resulting in irregular prints. For example, during hot stamping, the edges of the design may become jagged, affecting print quality. To ensure quality, the stamping mechanism’s pressure cushion must accurately match the design area without shifting, ensuring the design aligns with the cushioning layer during stamping to avoid fraying edges.

Do you want to

CUSTOM YOUR PREMIER GOODS

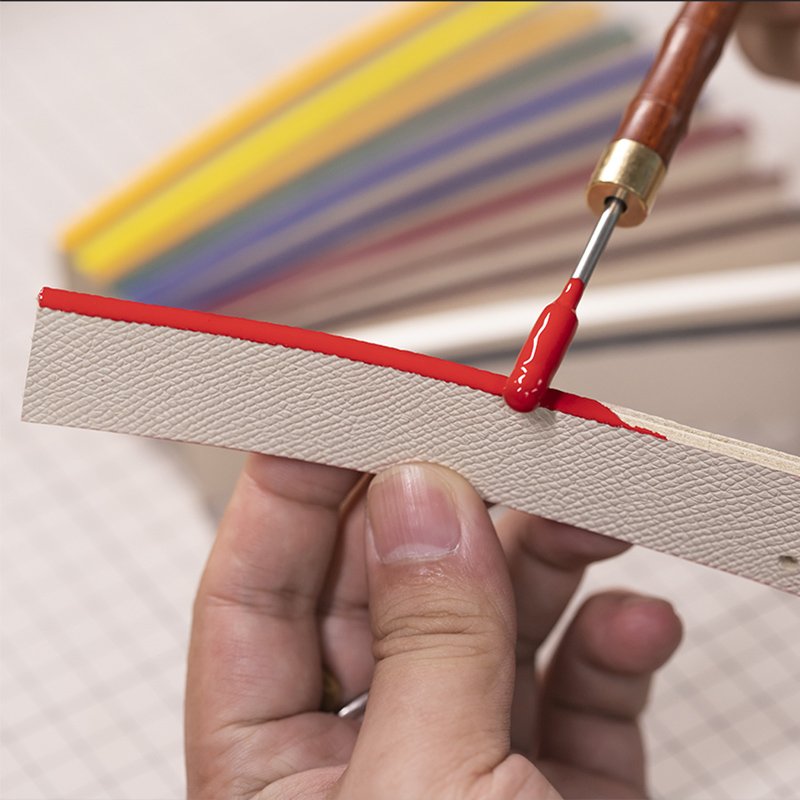

JINQ provides expert leather wrapping services, including hot pressing, sewing, edge painting, and custom leather solutions for electronics, packaging, gifts, stationery, and automotive interiors.

3. Paper-related Factors

Uneven pressure on the paper feed roller during transport can lead to paper bulging in the middle when it is aligned at the front. After pressing, this bulge forms creases. Inconsistent gripping force of the grippers on the printing cylinder can also cause wrinkles. Paper handling during transport before pressing can result in changed paper dimensions, causing wrinkling. Ink adhesion on the printing cylinder, improper paper positioning, and environmental factors like temperature and humidity can also cause paper wrinkles.

4. Processing-related Factors

Incorrect moisture content in materials can seriously affect the finished product’s size stability and bonding strength. Moisture levels should be measured before processing with an error margin of ±2%. Inaccurate processing can result in poor bonding, while uneven glue application can reduce bonding strength or cause areas to become unglued. Additionally, improper curing time and insufficient temperature during hot pressing can lead to weakened bonding strength. Adjusting hot press parameters such as temperature and pressing time is crucial to ensuring even bonding.

III. Solutions to Address Uneven Hot Stamping Veneer

1. Humidity Control

Installing humidity control equipment: Installing professional dehumidifiers and humidifiers in production workshops can maintain the humidity level at an optimal range (40%-60%) depending on the season. Proper storage management, using sealed packaging with desiccants, is also essential to prevent material dampness.

2. Ensuring Evenness of Printing Plates

Regularly inspect printing plates: Ensure plate flatness using specialized tools like levels. Inaccuracies greater than 0.05mm should be corrected or replaced. Using proper installation tools and trained personnel ensures better plate alignment.

3. Optimizing Paper Handling

Adjust pressure on the paper feed roller: Regularly check the roller pressure, ensuring it’s appropriate based on paper thickness. Balancing gripping force, proper handling during paper transport, and regular cleaning of printing cylinders prevent issues.

4. Strict Control During Processing

Precise control of material moisture content: Strictly measure material moisture before processing and ensure uniform glue application. Curing times should be adjusted based on environmental factors, and hot press parameters should be set appropriately based on the material.

Do you want to

CUSTOM YOUR PREMIER GOODS

JINQ provides expert leather wrapping services, including hot pressing, sewing, edge painting, and custom leather solutions for electronics, packaging, gifts, stationery, and automotive interiors.

IV. Future Outlook on the Quality of Export Products Using Hot Stamping Veneer

With the continuous development of global trade, the quality requirements for export products are rising. Uneven veneer affects both product quality and market competitiveness. By focusing on solving this issue, manufacturers can improve product quality, enhance competitiveness, and build trust with customers.

In conclusion, addressing the problem of uneven hot stamping veneer is essential for improving product quality and market performance in the export sector. Solutions require cooperation among enterprises, industry associations, and government authorities to foster healthy growth in the export industry.

V. Our Company’s Expertise in Veneer Processing

Shenzhen JINQ Technology Co., Ltd. has over 15 years of experience in customized veneer processing services, with leading industry expertise. We resolve 99% of veneer-related issues.

We have a professional team with advanced skills in veneer technology, constantly mastering the latest techniques to ensure top-notch quality. Our production equipment includes automated veneer systems, increasing efficiency by over 30%. Quality control is rigorous, with comprehensive checks at every stage, from raw material selection to final inspection.

Our customer-focused service includes personalized veneer customization and timely deliveries, ensuring satisfaction and high-quality products for all clients.