At Shenzhen JINQ Technology Co., Ltd., we implement precise and systematic methods to ensure the accuracy of cutting sizes in our hot press veneer process. Our commitment to precision helps minimize material waste and maintain high-quality standards. Below are the key steps we take:

Use of Accurate Measuring Tools

We utilize high-quality, precise measuring tools such as tape measures, rulers, and calipers to ensure that measurements meet the required accuracy. Our tools are regularly calibrated to avoid errors that could lead to incorrect cutting sizes. For more complex veneer shapes, we employ advanced 3D measuring equipment like laser scanners to capture highly accurate dimensional data.

Standardized Measurement Methods

Our team follows standardized measurement practices to ensure consistent results. This includes making sure that the start and end points of measurements are accurate. For curved surfaces, we apply a segmented measurement approach, adding up the lengths of each segment for improved accuracy. We also ensure that the measuring tools are perpendicular to the veneer surface, and that the veneer is laid flat during measurement to prevent distortion from external forces.

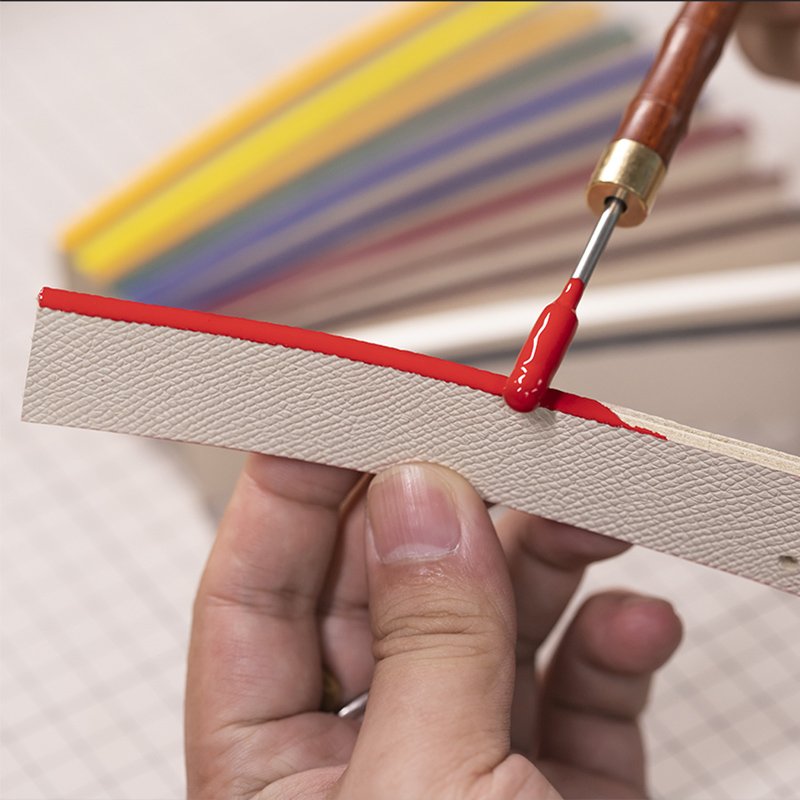

Template Creation

For veneers that require repeated cutting, we create custom templates. These templates are made from durable materials such as plastic boards or thick cardboard, ensuring precise cutting each time. By placing the veneer on the template and cutting along its edge, we guarantee size consistency. We routinely inspect and maintain the templates to ensure their accuracy, repairing or replacing them as needed.

Operator Training

Our cutting operators receive specialized training to familiarize themselves with the correct use of measuring tools and cutting techniques. The training covers proper measurement posture, how to read measurements, and the correct sequence for cutting. We emphasize the importance of careful attention and accuracy, requiring operators to double-check measurements before cutting and to work with precision during the process.

Post-Cutting Quality Inspection

After the cutting process, we conduct thorough quality inspections. Our team uses measuring tools to spot-check the cut veneers to ensure they meet the required size specifications. If any veneers are found to be outside the tolerance range, we make the necessary adjustments or re-cuts before moving to the next production stage, preventing material loss or further defects.

Equipment Maintenance

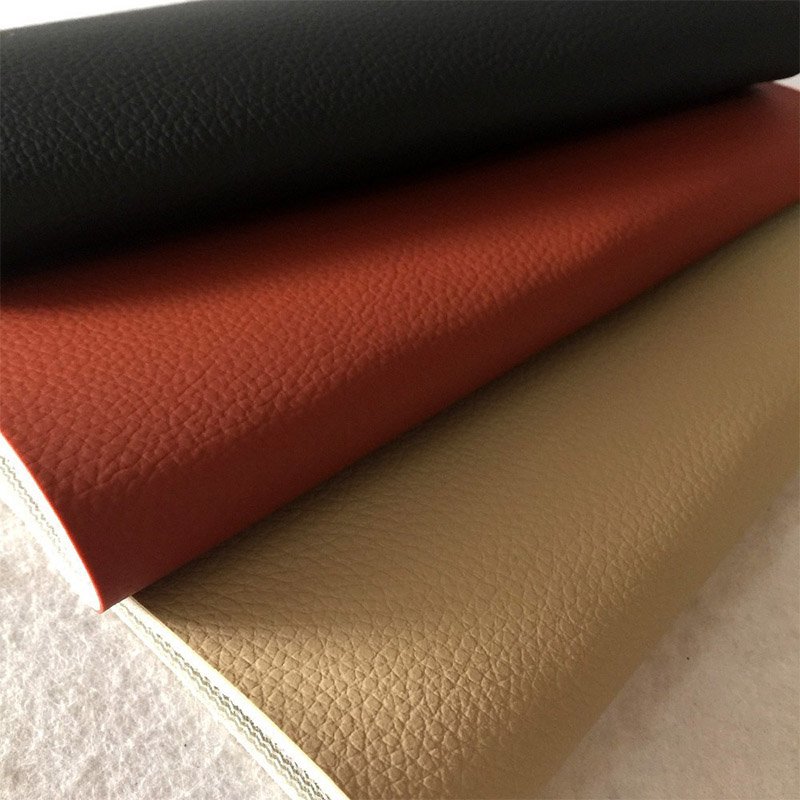

Regular maintenance of our cutting equipment is a priority at Shenzhen JINQ. This includes checking for tool wear and replacing dull blades promptly to maintain cutting precision. We also adjust machine parameters, such as cutting speed and pressure, to suit different veneer materials and thicknesses, ensuring optimal cutting accuracy.

Through these rigorous methods, Shenzhen JINQ Technology Co., Ltd. ensures that every piece of veneer is cut with precision, reducing material waste and maintaining the high quality our clients expect.