At Shenzhen JINQ Technology Co., Ltd., we implement a series of effective strategies to save raw materials through our hot pressing lamination processes. These methods are designed to optimize efficiency, reduce waste, and enhance overall sustainability:

Optimized Design and Planning

In the initial stages of product development, our team meticulously calculates the exact area and dimensions of the laminate required. This allows us to avoid excessive cutting and unnecessary material waste. By strategically planning the layout based on product shape and specifications, we minimize scrap generation. For more complex designs, we leverage advanced CAD software to simulate and find the most material-efficient solutions.

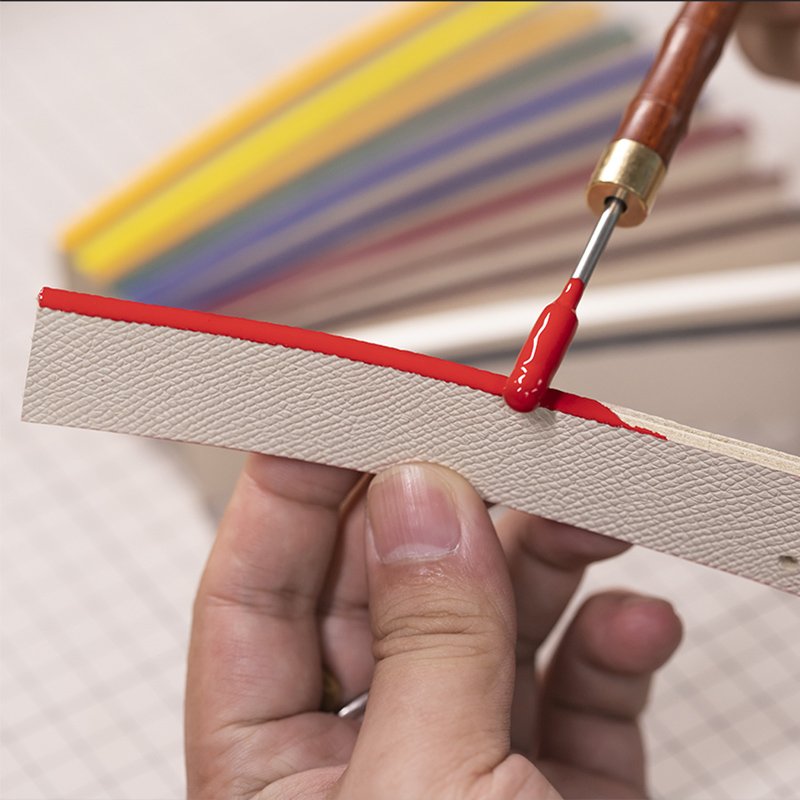

Precision Cutting Technology

We employ advanced cutting equipment that ensures high-precision cutting to exact specifications. This level of accuracy reduces the risk of material wastage from over- or under-cutting. Our machines are regularly maintained and calibrated to ensure stable performance, allowing us to maintain high-quality output while minimizing errors.

Maximizing Scrap Utilization

At Shenzhen JINQ, we are committed to making the most of every piece of material. Larger scraps are repurposed by splicing them into suitable areas, or by using them to create smaller accessories or product samples. Smaller scraps are recycled and used as filling materials or decorative elements in non-essential parts of products, contributing to a nearly waste-free process.

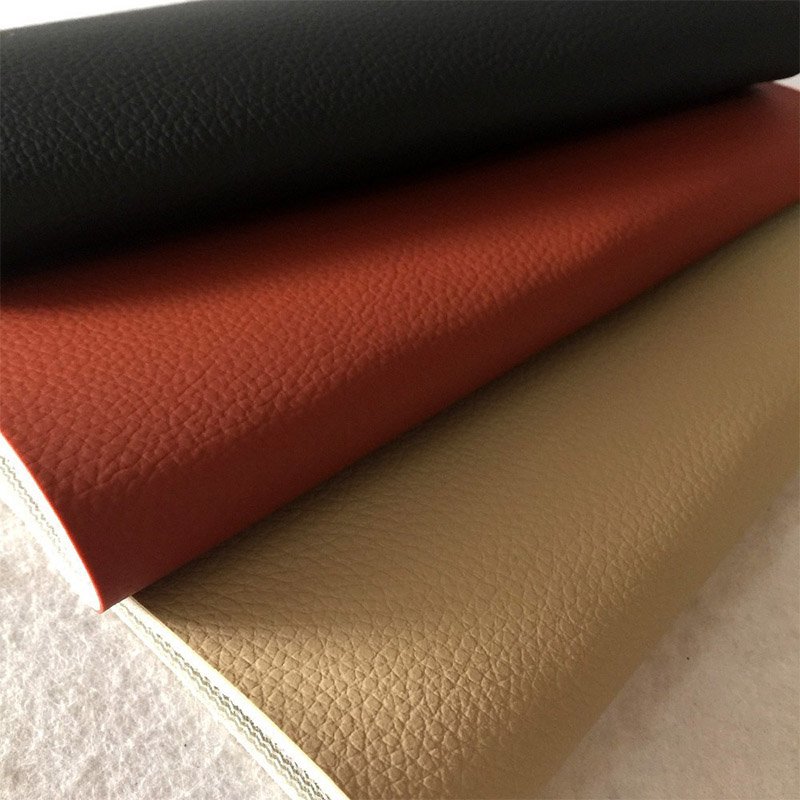

Strict Quality Control of Raw Materials

We source high-quality hot-pressed laminates that meet strict specifications to ensure minimal defects during processing. This reduces waste from faulty materials. Our rigorous inspection process helps us identify and eliminate defective portions early, improving the utilization rate of our raw materials.

Optimized Production Workflow

Our production processes are optimized to minimize waste at every stage. For instance, we laminate larger products first and then utilize the leftover materials for smaller items, ensuring no material is wasted. Additionally, we monitor the production line in real time to promptly identify any issues, allowing for immediate corrections. We also train our staff to increase their operational efficiency and awareness of material conservation.

Collaborative Supplier Partnerships

We work closely with our raw material suppliers to secure favorable purchasing terms, including bulk orders and long-term contracts that reduce material costs. We also collaborate with suppliers to explore ways of improving material efficiency, such as optimizing material specifications and packaging to reduce waste during transportation and storage.

By following these practices, Shenzhen JINQ Technology Co., Ltd. not only reduces raw material consumption but also enhances operational efficiency and contributes to environmental sustainability.