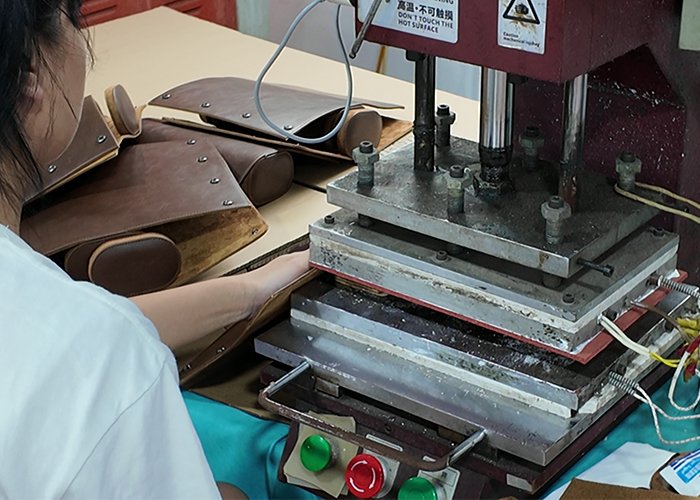

Hot Pressing Process

The hot pressing process is a technique that combines materials through heat and pressure. We utilize advanced hot press machines to ensure precise control of temperature and pressure for optimal bonding results. The main steps include:

- Material Preparation: Selecting suitable substrates and adhesives.

- Heating: Raising the materials to a specific temperature to activate the adhesive properties.

- Applying Pressure: Applying uniform pressure while at high temperature to ensure tight bonding of the materials.

- Cooling: Cooling the materials under appropriate pressure to cure the adhesive and ensure a strong bond.

High Strength

The hot pressing process achieves greater adhesive strength, ensuring the durability of the final product.

Uniformity

With precise control over temperature and pressure, every bond is uniform, minimizing weak points.

Wide Applicability

Capable of bonding various materials (such as leather, fabric, plastic, etc.), expanding its range of applications.

High Production Efficiency

Hot pressing typically operates faster than other bonding methods, improving overall production efficiency.

Application Areas

The hot pressing process is widely used across multiple industries, including but not limited to:

Automotive

Bonding interior materials to enhance the overall comfort and aesthetics of vehicles.

Furniture

Effectively combining different materials in high-end furniture to create more design-oriented products.

Electronics

Used in the assembly of electronic products to bond protective layers, ensuring device safety.

Fashion

In clothing and accessories, hot pressing can achieve complex designs and patterns, adding value to products.