Shenzhen JINQ Technology Co., Ltd. employs advanced machinery to ensure the precision and quality of their leather wrapping processes. Below are the key pieces of equipment used:

1. Cutting Equipment

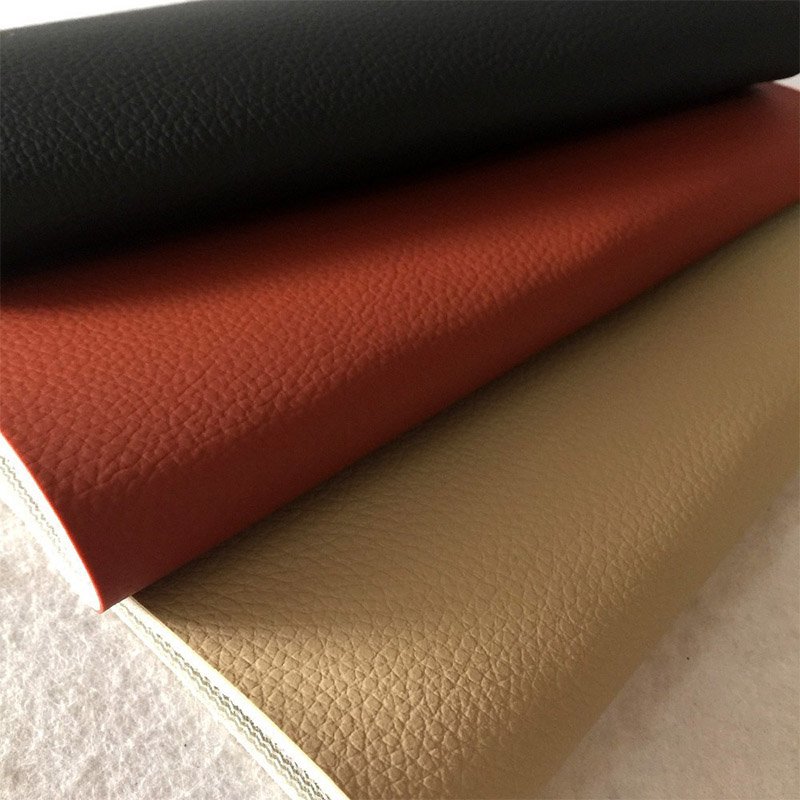

- Leather Cutting Machine: This machine is designed for precise leather cutting and is adjustable for various shapes and sizes. Shenzhen JINQ uses both manual and automatic machines, with the latter increasing cutting efficiency and precision.

- Hand Tools: Including leather knives and scissors, these tools are essential for manual trimming and refining the edges after using the cutting machine.

2. Bonding Equipment

- Hot Press Machine: This machine utilizes heat and pressure to bond leather to its base material. Adjustable for temperature, pressure, and time, the hot press ensures a strong adhesion based on the specific materials and processes used at Shenzhen JINQ.

- Glue Spraying Machine: To ensure secure bonding, a glue spraying machine is employed to evenly coat adhesive on either the leather or base. Automatic versions enhance uniformity and efficiency, vital for large-scale production.

3. Sanding Equipment

- Sanding Machine: This machine smooths the leather edges for an even, polished finish. Shenzhen JINQ Technology uses sandpapers of varying grit to achieve the desired surface quality.

- Grinder: For larger surfaces or more extensive sanding tasks, a grinding machine is utilized. Operators carefully control the speed and pressure to avoid over-sanding, protecting the material’s integrity.

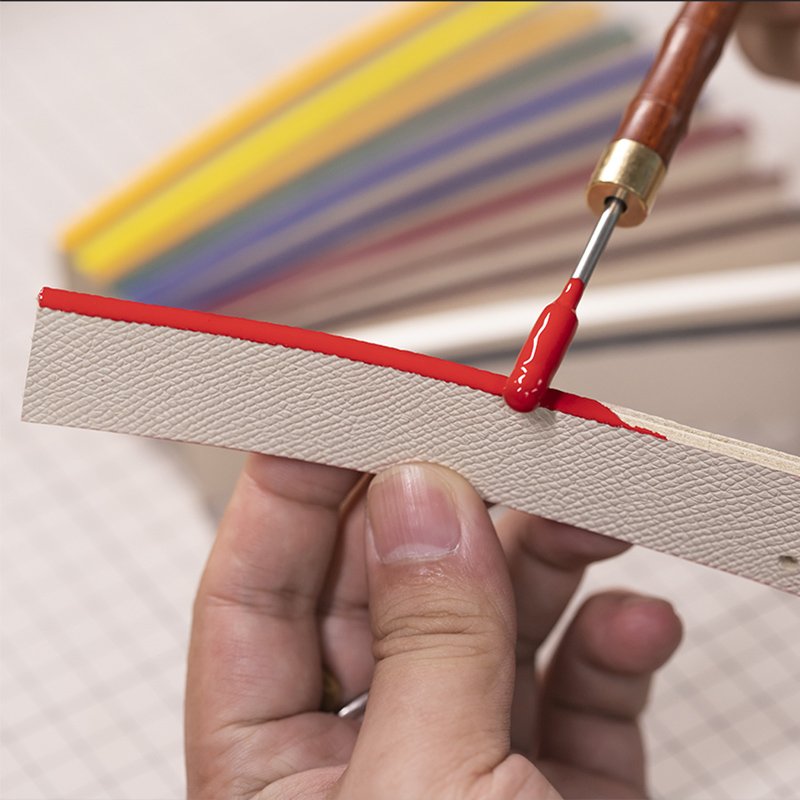

4. Edge Finishing Equipment

- Edge Oil Machine: Shenzhen JINQ applies this machine specifically for treating the edges of leather with oil, ensuring consistency in application and enhancing the overall quality. The machine can be adjusted for different widths and colors of edge oil.

- Drying Machine: To expedite the drying process after oiling, the drying machine helps to speed up production while ensuring that the finish is smooth and durable.

5. Other Auxiliary Equipment

- Workbenches: A stable workspace is essential for efficient and precise operations. Shenzhen JINQ uses custom-sized workbenches to facilitate the various steps in the leather wrapping process.

- Clamps: These are used to secure the leather and base material in place during operations, preventing movement and ensuring accuracy.

- Vacuum Cleaner: To maintain a clean working environment, vacuum cleaners are utilized to remove dust and debris generated during cutting and sanding.