1. The Importance of Leather Wrapping Factories

Leather Wrapping factories occupy a crucial position in the leather goods industry. First, they are a vital link between raw materials and finished products. According to the article, the leather industry encompasses main sectors such as leather tanning, footwear, leather garments, leather goods, fur products, and auxiliary sectors like leather chemicals, hardware, machinery, and accessories. In this vast industrial chain, Leather Wrapping factories are responsible for processing and packaging leather, transforming it into marketable goods.

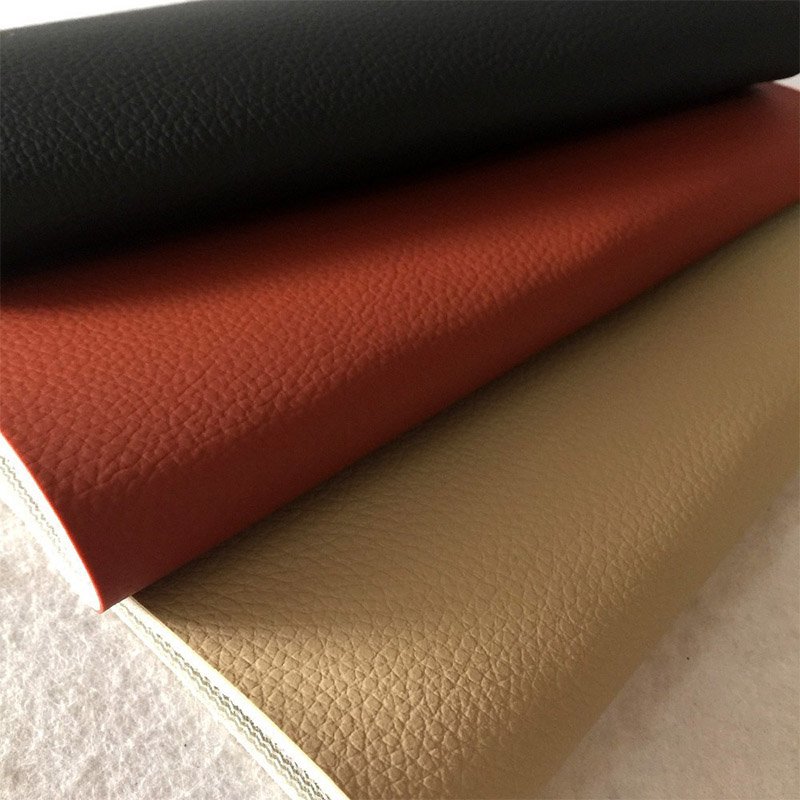

The role of a Leather Wrapping factory is not just simple packaging but also enhancing the quality and value of leather products. With exquisite craftsmanship and professional techniques, factories can turn ordinary leather materials into finely crafted products, meeting consumers’ demands for high-quality and personalized items. For example, different types of leather such as patent leather, genuine leather, waxed leather, suede, and nubuck, as mentioned in the article, require specific processing techniques to reveal their unique charm.

Moreover, Leather Wrapping factories drive the development of the leather industry. On the one hand, technological innovations and process improvements in factories can enhance the quality and performance of leather goods, thus increasing industry competitiveness. For instance, the article highlights the introduction of nanotechnology in leather dyeing, which improves processing performance, production efficiency, and surface strength. Also, the use of 3D printing, cutting, and scanning can aid in shaping, tanning, and processing leather. On the other hand, factory production scale and market demand influence the procurement and supply of raw materials, promoting coordinated development across the industrial chain.

In summary, Leather Wrapping factories hold an irreplaceable position and play a pivotal role in the leather goods industry.

2. Essential Competencies in Production Techniques

(1) Selection and Pre-treatment of Raw Materials

High-quality leather goods start with carefully selected raw hides. Leather Wrapping factories should establish long-term relationships with reliable suppliers to ensure access to top-quality natural leather like cowhide, sheepskin, and pigskin. The article notes that different types of leather have distinct characteristics; for example, cowhide is durable, sheepskin is soft, and pigskin is relatively inexpensive. Factories must select appropriate raw materials based on product positioning and customer needs.

The pre-treatment process is vital for leather quality. Optimizing soaking and dehairing techniques can enhance the quality of leather. For instance, adjusting the composition and concentration of soaking agents improves permeability and desalination effects, reducing soaking time and water pollution. Similarly, optimizing dehairing agent formulations and process parameters can improve dehairing results and reduce leather damage. Strict control over pre-treatment processes ensures stability and reliability.

(2) Tanning Process Improvement

Advanced tanning technology is essential for improving leather’s softness, elasticity, and durability. Traditional chrome tanning provides excellent leather performance but is toxic, posing environmental and health risks. Therefore, factories should actively adopt chrome-free tanning technologies like vegetable tanning, synthetic tanning, and enzyme tanning.

Vegetable tanning has a long history, is environmentally friendly, and produces leather with unique textures and appearances. Enzyme tanning is advantageous due to its mild reaction conditions, environmental friendliness, and high-quality leather products. Optimizing tanning agent formulations, shortening tanning times, and increasing efficiency can lower production costs while enhancing leather performance.

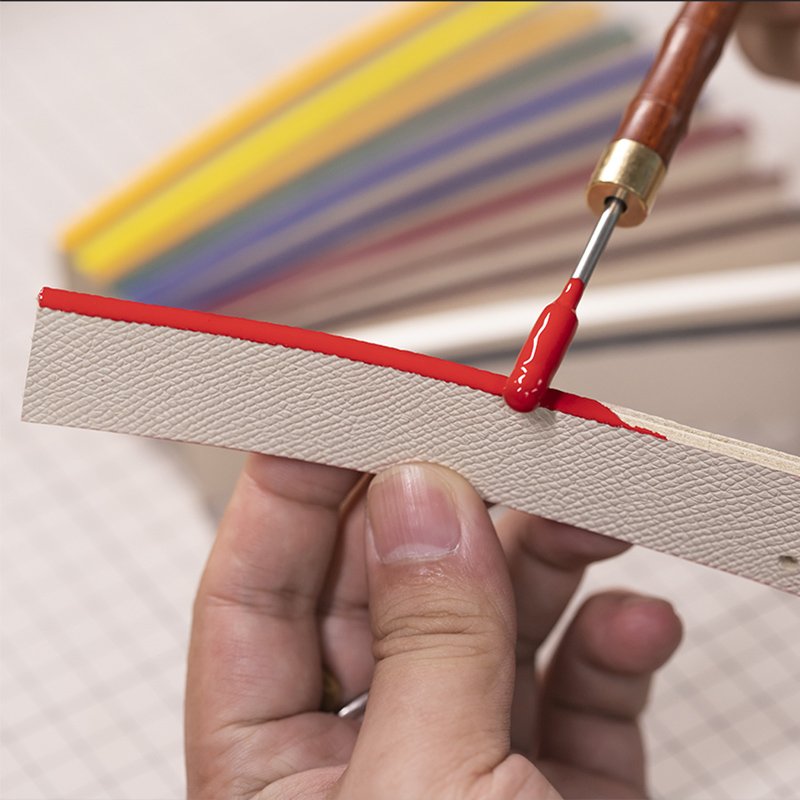

(3) Dyeing and Finishing Innovations

Incorporating trendy elements into design, using eco-friendly materials and processes for dyeing and finishing, can make leather products more attractive and competitive. The article notes that natural pigments are increasingly used in leather dyeing. Extracted from plants, animals, and minerals, natural pigments like madder, indigo, and hematoxylin are sustainable and environmentally friendly.

Optimizing dyeing techniques, such as multi-stage or gradient dyeing, can achieve richer colors and more uniform results. In finishing, eco-friendly materials like organic-inorganic nanocomposites enhance leather’s abrasion resistance, waterproofing, and antibacterial properties. Innovative technologies like digital printing can achieve personalized and customized leather dyeing, meeting consumer demand for unique products.

3. Essential Competencies in Quality Control

(1) Rigorous Quality Inspection Systems

Leather Wrapping factories need to establish strict quality inspection systems to ensure products meet industry standards and customer requirements. Firstly, internal quality inspection standards should be developed based on national and industry regulations, such as GB/T19665-2011 (General Technical Conditions for Leather Garments), GB/T19666-2011 (General Technical Conditions for Leather Shoes), and GB/T19667-2011 (General Technical Conditions for Leather Bags).

From a physical performance perspective, tests on leather goods should include strength, elongation, tear resistance, wear resistance, and water resistance. The article cites Esslite (Qingdao) Massage and Leisure Equipment Manufacturing Co., Ltd., which requires leather to withstand 200,000 rubs in both warp and weft directions without visible damage or peeling, based on ASTM D4157-2013. From a chemical perspective, factors like pH, color fastness, formaldehyde content, and heavy metal content should be tested, in line with American and Chinese standards.

Appearance-wise, the surface quality, color uniformity, sewing quality, and hardware of leather goods must be inspected. Defects such as breakage, scratches, color stripes, and uneven thickness should be avoided. Comprehensive quality checks can help identify and rectify issues promptly, ensuring that every product leaving the factory meets high-quality standards.

(2) Risk Warning and Supply Chain Coordination

Establishing a supply chain risk warning system is crucial for Leather Wrapping factories. Raw material price fluctuations, production risks, logistics issues, market risks, and financial risks must be thoroughly assessed. Strengthening collaboration with supply chain partners and adopting supply chain visualization management ensures efficient communication and timely responses to potential risks.

4. Essential Competencies in R&D and Innovation

(1) Design Concepts that Integrate Fashion and Functionality

Leather Wrapping factories must keep a keen eye on international fashion trends. Drawing inspiration from fashion shows, factories should design leather products that combine style with functionality. The integration of fashion design with smart production is becoming a trend. For example, factories could design smart leather bags with light-sensitive color adjustment or anti-theft features.

(2) Building and Motivating R&D Teams

A multi-disciplinary R&D team is essential for innovation in Leather Wrapping factories. Team members should include leather processing experts, fashion designers, material scientists, and engineers. Effective incentive mechanisms, such as bonuses and equity, should be implemented to inspire innovation.

(3) Showcasing and Promoting Innovation

Leather Wrapping factories should showcase their innovations at international trade fairs and fashion shows to increase brand visibility. Utilizing social media and online platforms for promotion can attract potential customers.

5. Essential Competencies in Management and Operations

(1) Familiarity with ISO Management Systems

ISO management systems play a significant role in factory operations. ISO9001 ensures quality management, ISO14001 focuses on environmental management, and ISO45001 improves occupational health and safety management. Adhering to these standards enhances factory performance, product quality, and employee well-being.

(2) Strong Communication and Coordination Skills

Effective communication and coordination are essential for smooth operations. Good communication ensures seamless information transfer between departments, improving efficiency and resolving conflicts.

(3) Execution and Project Management

Strong execution capabilities are vital for a Leather Wrapping factory. Quick response to market demands, optimized service processes, and efficient project management help factories stand out in competitive markets.

6. Future Outlook

(1) Environmental Trends

Leather Wrapping factories must focus on sustainability by adopting eco-friendly raw materials and production technologies to reduce environmental impact.

(2) Smart Manufacturing Trends

Factories should embrace advanced intelligent manufacturing technologies, including big data analysis, IoT, and AI, to improve efficiency and quality.

(3) Personalized Customization Trends

Meeting the growing demand for personalized products through customization tools and AI-driven customer insights will be key.

(4) Continuous Innovation and Capacity Building

Leather Wrapping factories must continue innovating and upgrading their capabilities to remain competitive in the future. By keeping up with fashion and technological trends, factories can provide high-quality, eco-friendly, and personalized leather products.