1. Leather Coating Process

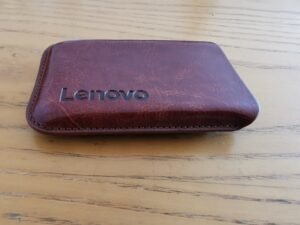

This term emphasizes the use of leather to cover and wrap objects, enhancing their appearance and durability. The leather coating process is widely used in the automotive, furniture, and luxury goods industries to give a premium, polished finish.

2. Leather Decoration Bonding Process

This name highlights the role of leather as a decorative material that is bonded to other substrates. The leather decoration bonding process focuses on the adhesion between the leather and various materials like wood, metal, or plastic, ensuring a seamless integration of both function and style.

3. Leather Sheathing Process

The term “sheathing” refers to the act of covering an object with a protective layer, often used in the context of leather. The leather sheathing process is commonly applied in the production of automotive interiors, where leather is used to sheath surfaces such as steering wheels, dashboards, and gear shifts for both protection and aesthetic appeal.

Do you want to

CUSTOM YOUR PREMIER GOODS

JINQ provides expert leather wrapping services, including hot pressing, sewing, edge painting, and custom leather solutions for electronics, packaging, gifts, stationery, and automotive interiors.

4. Leather Lamination Process

This term underscores the lamination aspect of leather wrapping, where leather is combined or laminated with other materials. The leather lamination process is often utilized to create durable and stylish products, ensuring the leather adheres to the underlying material while maintaining its luxurious texture and appearance.

In conclusion, leather wrapping techniques go by various names, depending on the focus of the process. Whether it’s emphasizing the coating, bonding, sheathing, or lamination, each term captures a different facet of this highly versatile and widely used craft.